The long fibers in UD fabric are arranged in a straight and parallel manner in the matrix material, and the strength loss of the fibers during processing is minimal, which can fully utilize the unique advantages of the microfiber itself. Therefore, the finished product has excellent ballistic performance and is mainly used for soft bulletproof clothing.

The basic structure of para aramid UD fabric is two or more layers of unidirectional weft free fabric arranged in a certain fiber axis rotation angle (mostly 0 °/90 °/0 °/90 °), which are crossed and laminated with adhesive to form a soft film form. It differs greatly from traditional bulletproof materials (such as woven fabrics, knitted fabrics, woven fabrics, etc.) in terms of forming structure, processing technology, and elastic resistance. The long fibers in weft free fabric are arranged in a straight and parallel manner in the matrix material, and the strength loss of the fibers during processing is minimal, which can fully utilize the unique advantages of the microfiber itself. Therefore, the finished product has excellent ballistic performance and is mainly used for soft bulletproof clothing.

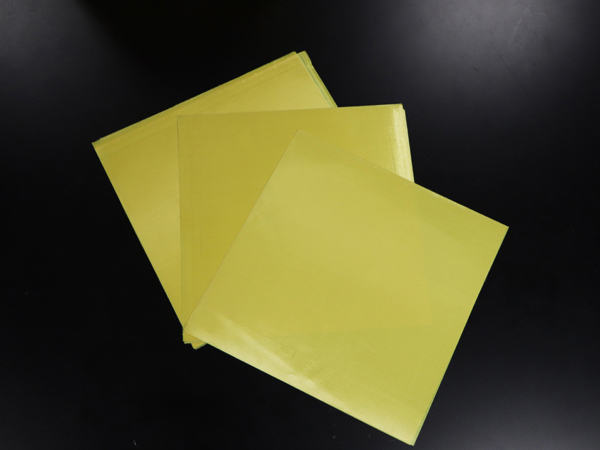

Performance indicators of para aramid UD fabric

| UD Fabric Type | Filament | UD Fabric Structure | Weight g/m2 |

|---|---|---|---|

| THUD401 | 629-1100/667f | 0/90°Continuous | 240 |

| THUD402 | 629T-1100/667f | 0/90°Continuous | 235 |